What is Programmable Logic Controller and How PLC work?

In today’s world, automation is the driving force behind increased efficiency and precision in industrial processes. At the heart of this automation revolution lies the Programmable Logic Controller (PLC). Programmable logic controllers play a crucial role in industrial automation, ensuring the precise control and monitoring of various processes and machinery. In this blog post, we will explore what is plc, its types, plc programming and its languages, how PLC work and their significant impact on various industries.

“From powering assembly lines to controlling traffic lights, Programmable Logic Controllers (PLCs) are the unseen architects of our modern, automated world.”

What is plc?

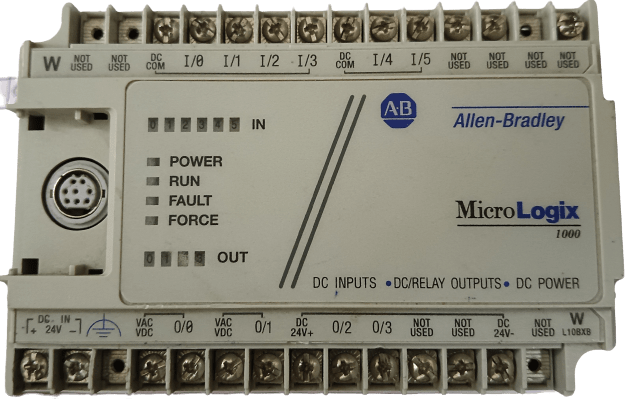

PLC stands for “programmable logic controller”. It is a specialized computer system used in industrial automation and control system to monitor and control machinery and processes.

PLCs are designed to receive input signals from sensors and switches, process this input using program or logic developed by PLC programmer, and then produce output signals to control devices, such as motors, valves, and relays, to perform specific tasks or processes.

PLCs are commonly used in industries, manufacturing plants, factories, and other industrial settings to automate various tasks and processes.

Here are some key characteristics of PLC:

- Logic Control: PLC performs or we can say, PLCs execute logical operations based on input data and a user programmed logic. This logic can be represent with the help of PLC programming languages like ladder diagrams, function block diagrams, structured text, or sequential function charts.

- Real-Time Operation: Many PLCs operate in real-time, responding to input signals and executing control logic within milliseconds. This real-time is crucial for tasks requiring precise timing and synchronization.

- Flexibility: PLCs are highly flexible and can be reprogrammed to adapt to changing production requirements or process conditions.

- Communication: PLCs often support communication protocols to exchange data with other devices and system. Communication occurs with human-machine interface (HMI), supervisory control and data acquisition (SCADA) systems, and other PLCs.

Types of PLC

Programmable Logic Controller(PLC) comes with various types, each plc is designed for specific tasks i.e. applications and industries. The main types of plc are:

- Modular PLC: The modular PLCs are built using individual modules that can be customized and assembled to meet specific requirements. It offers flexibility regarding input/output options and can expand and upgrade according to manufacturer requirements. Modular PLCs are suitable for applications where scalability and customization are essential.

- Compact PLC: Compact PLCs are small in size and have a fixed number of input and output points. The Compact PLCs are used in applications where the requirements of I/O are not larger. It is designed in such a way that the size it takes limited space or where a smaller number of I/O points are sufficient.

- Rack-Mountable PLCs: These PLCs are designed to be mounted in standard equipment racks or cabinets. They are commonly used in industrial automation systems where space is a consideration. Rack-mountable PLCs can be modular or fixed configurations, depending on the model.

How PLC Work

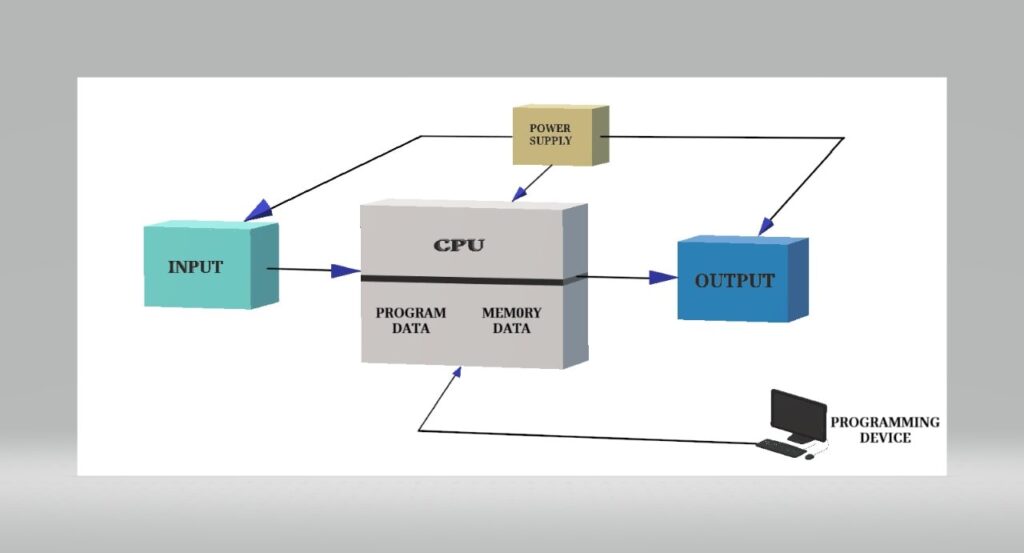

PLCs are a popular choice in manufacturing, automation, and other industries as they offer a more efficient and flexible solution compared to traditional relay-based control systems. The three main components of a PLC are Inputs, Outputs, and Processing Unit (CPU).

Fig.1 How PLC work

Here’s a simple explanation of how PLC work:

A) Inputs

Programmable logic controllers (PLCs) receive electrical or electronic signals from sensors, switches, and devices within industrial or automation systems. These input signals are utilized by the PLC to monitor and control the process. PLC inputs are classified into different types based on their characteristics and applications.

Below are some of the most common types of PLC inputs:

- Digital inputs: on/off switch, sensors, limit switch, push buttons, and other devices that provide a simple ON/OFF signal.

- Analog inputs: pressure sensors, resistance temperature detector, etc. PLCs convert the analog input signal into digital data that can be processed in the control program.

- Communication Inputs: PLCs can receive the input data from external sources through communication interfaces, such as Ethernet, serial ports. This allows the PLC to communicate with other PLCs, Human-Machine Interface (HMIs), or external sensors and devices.

B) CPU

It is the brain of the PLC, responsible for making decisions on the control program and the status of input devices, and then executing those decisions to control output devices and manage the industrial process. Here’s an overview of what the CPU does in a PLC:

- Program Execution

- Input Processing

- Output Control

- Timing and Sequencing

- Error Handling

- Memory Management

C) Outputs

A Programmable Logic Controller (PLC) in an industrial or automation system relies on electronic or electrical signals as output to effectively control devices and components. These outputs must execute actions or commands based on the specified logic programmed in the control program.

The following are some typical types of PLC outputs:

- Digital Outputs: Digital outputs represent two states: ON (1) or OFF (0), and are used to control binary devices such as motors, solenoids, relays, and indicators lights. Digital outputs can turn devices on or off, open or close valves, or activate alarms.

- Analog Outputs: It provides a continuous signal with varying voltage or current levels. They are used for controlling devices that requires precise analog control, such as variable frequency drives (VFDs), proportional valves, and heating elements. PLCs convert digital control signals into analog signals to regulate the output.

- Specialized Outputs: Some PLCs may have specialized output types for specific applications, such as pulse-width modulation (PWM) outputs for motor speed control, stepper motor control outputs, or output relays for switching high-power loads.

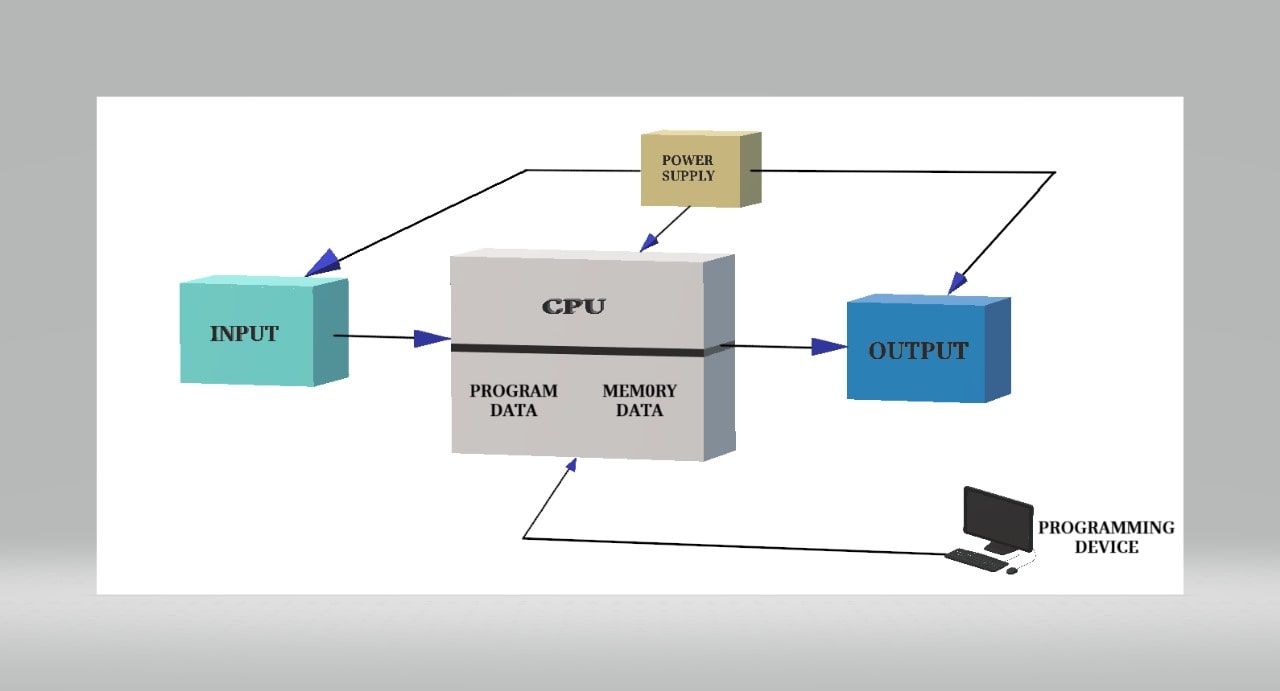

Fig.2 How PLC work Diagram

PLCs are machines that operate based on a program. This program is written in a language called ladder logic or function block diagram (FBD). These languages use graphical symbols to represent logical and arithmetic operations. The program is made up of a series of “rungs”. Each rung contains specific instructions that dictate how the PLC should react to different input conditions and trigger various output actions.

PLCs consist of several key components including CPU and I/O that works together to control and monitor processes:

PLCs consist of several key components including CPU and I/O that works together to control and monitor processes:

- Memory: PLCs have two main types of memory:

- Program memory: This memory stores the user’s control logic program. It’s where the ladder logic or other programming language is stored.

- Data memory: Data memory stores variables, timers, counters, and other runtime data needed for the control program to operate. It keeps track of the current state of the system.

- Communication ports: Modern PLCs come equipped with communication ports for data exchange and remote control with other devices, such as HMLs, computers, and other PLCs, enabling integration with larger automation networks.

- Power supply: A stable and reliable power supply is essential for the proper operation of a PLC. It provides the necessary voltage levels for the CPU, I/O modules, and other components.

This is How PLC work. The Programmable Logic Controller (PLC) is an essential tool for industrial automation and control. Its outputs features and capabilities can vary depending on the make and model of the PLC. However, users can personalize and adjust the outputs functionality through PLC programming.

PLC Programming

There are various PLC programming languages available, with each one designed for specific tasks and applications. Here are some commonly used languages:

- Ladder Logic (LAD)

- Structured Text (ST)

- Function Block Diagram (FBD)

- Sequential Function Chart (SFC)

- Instruction List

- Structured Control Language (SCL)

Each of these programming languages has its strengths and is chosen based on the specific requirements of the industrial application. The ladder diagram is the most commonly used language in industries.

Advantages of PLC

- Easy to program

- Faster Response time

- Can change input and output to plc many times

- No complex as we do most of the work in programming only

- Easy to troubleshoot

- Program can be changed multiple times

- Can handle complicated systems

- Make wiring easy and sorted

- Easy to expand with Modular PLC

- PLCs are specifically designed to operate continuously, 24 hours a day without any interruptions. This is what makes them incredibly durable and robust.

Disadvantages of PLC

- PLCs are expensive

- Lack of User-Friendly Interfaces

PLC Manufacturers

Choosing the right PLC manufacturer is crucial to ensure the success and reliability of your automation projects. In this blog post, we will explore some of the leading PLC manufacturers of industrial automation.

- Siemens

- Rockwell Automation (Allen-Bradley)

- Schneider Electric

- ABB

- Mitsubishi Electric

- Omron

- Delta Electronics

- Beckhoff Automation

- WAGO

- GE Automation & Control

When selecting a PLC manufacturer for your automation project, consider your specific requirements, budget, and the compatibility evolving, so staying up–to-date with the latest advancements in PLC technology is essential for achieving optimal results in your automation endeavors.

Applications of PLC

PLCs are useful in various applications depending on the specific program they are being used for. Here are some typical uses of PLCs.

- Manufacturing Automation

- Process Control

- Traffic Control

- Packaging and Material Handling

- Elevator control

- Transportation

If you want to learn more about the Applications of Programmable Logic Control (PLC) in detail then click here.

Understanding the significance of PLCs is an essential stepping stone into the realm of industrial automation, whether you’re an aspiring engineer, an automation enthusiast, or simply curious about the machinery powering our automated world. In the dynamic landscape of industrial automation, PLCs are the driving force behind a safer, more efficient, and increasingly automated future.

Nice

Very well done boys. Keep it up.